Chemical burr clean method is suitable for small metal parts

Principle and method of chemical burr clean:

Put the cleaned metal parts into the chemical solution (50 ℃), and the metal on the surface of the parts will be transferred into the solution in the form of ions. These ions gather on the surface of the metal workpiece and form a layer of viscous film with large resistance and small conductivity through chemical reaction to protect the surface of the workpiece from corrosion, while the burr protrudes out of the surface, and the chemical action will remove the burr.

Chemical burr clean method:

During processing, only one slot is needed. According to different deburring materials, different chemical solutions are used. The main components can be hydrochloric acid, phosphoric acid, sulfuric acid, diphenylamine hydrochloride and water, etc., which are prepared in proportion.

Chemical deburring is suitable for small metal parts, which can remove small burrs with thickness less than 0.07mm.

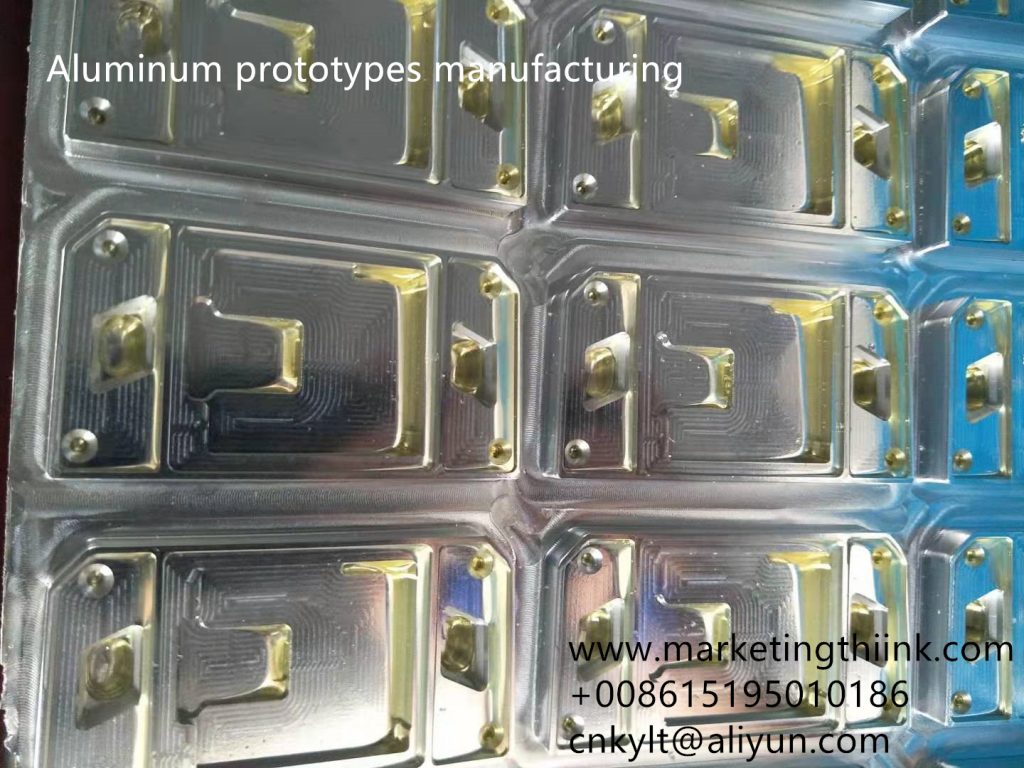

KYLT Precision CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making, Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

KYLT CNC Machining Services:

KYLT CNC Precision Machined Parts:

More information about Machining Technology:

评论

发表评论