Stainless steel widely used to produce all kinds of machinery part to avoid rust. But Stainless steel will rust under certain conditions.

Why does stainless steel rust?

When there are brown rust spots (spots) on the surface of stainless steel pipes, people are surprised to think that “stainless steel is not rusty, rust is not stainless steel, maybe there is a problem with the steel quality”. In fact, this is a one-sided wrong view of the lack of understanding of stainless steel. Stainless steel will rust under certain conditions.

Stainless steel does not rust

It also produces an oxide on the surface. At present, all stainless steel on the market is due to the presence of Cr element. The basic reason (mechanism) of stainless steel corrosion resistance is passivation film theory. The so-called passivation film is a layer of Cr2O3 based film on the surface of stainless steel. Due to the existence of this film, the corrosion of stainless steel matrix in various media is blocked, which is called passivation.

THERE ARE TWO CONDITIONS FOR THE FORMATION OF THIS PASSIVATION FILM.

1.One is that stainless steel itself has the ability of self passivation, which is accelerated with the increase of chromium content, so it has rust resistance;

2.The other is that stainless steel in various aqueous solutions (electrolytes) forms a passivation film in the process of corrosion, which hinders corrosion. When the passive film is damaged, a new passive film can be formed immediately.

THE PASSIVATION FILM OF STAINLESS STEEL HAS THREE CHARACTERISTICS:

1. the thickness of the passivation film is very thin, generally only a few microns when the chromium content is more than 10.5%;

2. the proportion of the passivation film is greater than the proportion of the substrate. These two characteristics show that the passivation film is thin and dense, so it is difficult for the passivation film to be broken down by the corrosion medium to quickly corrode the base body.

3. Third characteristic is that the chromium concentration of the passivation film is three times higher than that of the substrate, so the passivation film has high corrosion resistance.

Stainless steel will be corroded under certain conditions

The application environment of stainless steel is very complex, and the pure chromium oxide passivation film can not meet the requirements of high corrosion resistance. In order to improve the composition of passivation film and the corrosion resistance of stainless steel, molybdenum (MO), copper (Cu), nitrogen (n) and other elements should be added to the steel according to the different service conditions.

1.WHEN MO IS ADDED

the corrosion product MoO2 – is close to the substrate, which strongly promotes the collective passivation and prevents the corrosion of the substrate;

2.WHEN CU IS ADDED

the passivation film on the stainless steel surface contains CuCl, which improves the corrosion resistance because it does not interact with the corrosion medium;

3.WHEN N IS ADDED

the passivation film is rich in Cr2N, which increases the Cr concentration in the passivation film, thus improving the corrosion resistance of stainless steel.

THE CORROSION RESISTANCE OF STAINLESS STEEL IS CONDITIONAL.

One grade of stainless steel is corrosion-resistant in one medium, but it may be damaged in another medium. At the same time, the corrosion resistance of stainless steel is also relative. So far, no stainless steel is absolutely non corrosive in all environments.

Stainless steel has the ability to resist atmospheric oxidation, i.e. rust resistance, but also the ability to corrode in the medium containing acid, alkali and salt, i.e. corrosion resistance. However, the corrosion resistance of the steel varies with the chemical composition of the steel itself, the state of reinforcement, the conditions of use and the type of environmental medium.

For example, 304 steel pipe has absolutely excellent corrosion resistance in dry and clean atmosphere, but when it is moved to the seaside area, it will soon rust in the sea fog containing a lot of salt, while 316 steel pipe performs well. Therefore, not any kind of stainless steel can resist corrosion and rust in any environment.

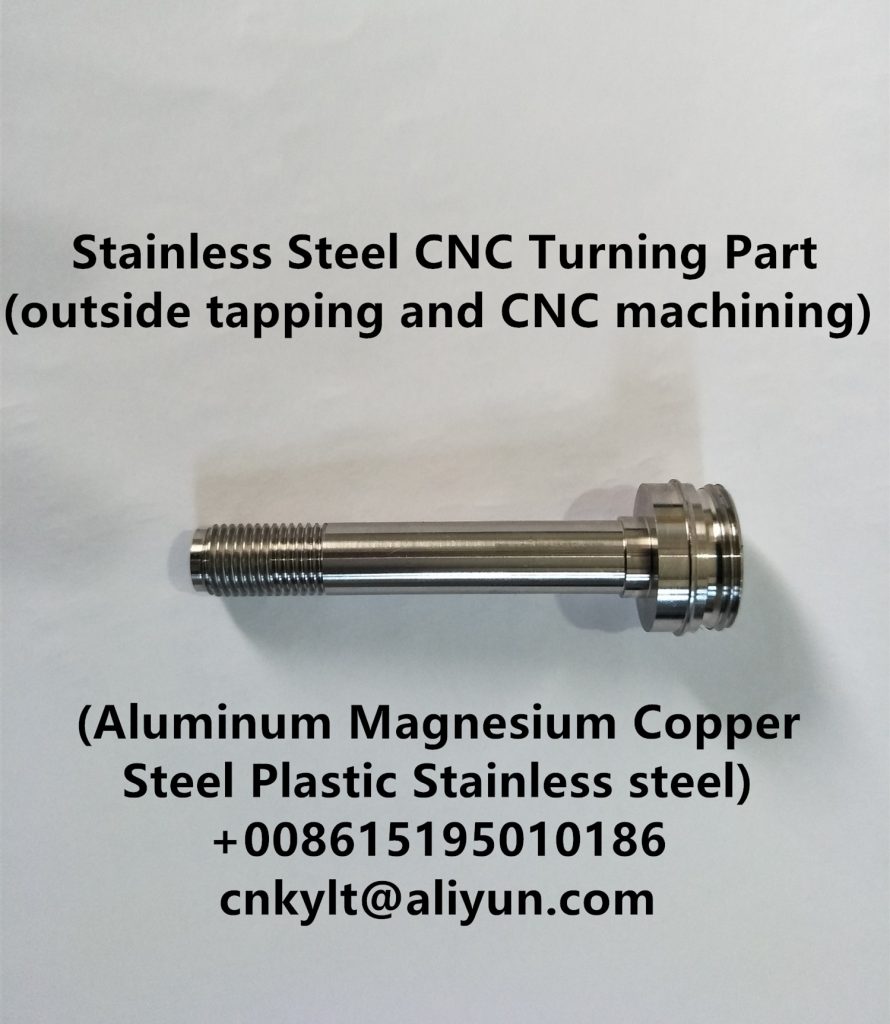

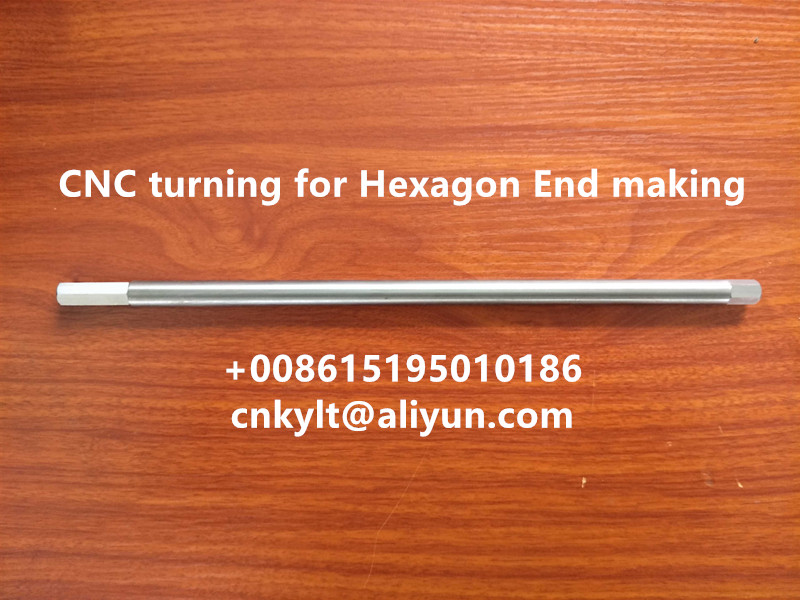

KYLT Precision CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making, Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

KYLT CNC Machining Services:

KYLT CNC Precision Machined Parts:

More information about Machining Technology:

评论

发表评论