Die Casting Machines Classification by Different Materials: A Comprehensive Guide

Die casting is a popular manufacturing process that involves the production of metal die casting parts and products. It is a cost-effective and efficient method of producing high-quality metal products in large quantities. Die casting machines are the backbone of this process. They are responsible for producing products that meet the highest industry standards. In this article, we will discuss the die casting machines classification by different materials.

Meta-Description

Learn about the die casting machines classification by different materials in this comprehensive guide. Get an in-depth understanding of the various types of die casting machines used in the manufacturing process.

Introduction

Die casting is a popular manufacturing process that is widely used in the production of a wide range of metal products. Die casting machines are an essential part of this process. They are responsible for producing high-quality metal die-cast parts in large quantities. In this article, we will discuss the die casting machines classification by different materials.

Die casting machines classification by different materials:

Die casting machines can be classified into several types based on the materials used in the manufacturing process. The different types of die casting machines are:

Aluminum alloy die casting machine

Aluminum die casting machines are the most commonly used type of die casting machines. They are used to produce a wide range of aluminum die-cast parts and products. These machines are highly efficient and cost-effective, making them a popular choice for manufacturers. ( Service & price: cnkylt@aliyun.com )

Magnesium alloy die casting machine

Magnesium die casting machines are used to produce a wide range of magnesium parts and products. These machines are highly efficient and can produce high-quality parts at a fast rate. They are commonly used in the aerospace and automotive industries. ( Service & price: cnkylt@aliyun.com )

Copper/Brass alloy die casting machine

Copper die casting machines are used to produce a wide range of copper parts and products. These machines are highly efficient and can produce high-quality parts at a fast rate. They are commonly used in the production of electrical components. ( Service & price: cnkylt@aliyun.com )

Zinc/Zamak alloy die casting machine

Zinc/ZAMAK die casting machines are used to produce a wide range of ZAMAK/Zinc parts and products. These machines are highly efficient and can produce high-quality parts at a fast rate. They are commonly used in the automotive industry, as well as in the production of electronic components. ( Service & price: cnkylt@aliyun.com )

Lead/PB alloy die casting machine

Lead/PB die casting machines are used to produce a wide range of lead parts and products. These machines are highly efficient and can produce high-quality parts at a fast rate. They are commonly used in the production of batteries. ( Service & price: cnkylt@aliyun.com )

Lead alloy die casting parts of lead acid battery terminal & bushing by horizontal/vertical die casting machine

Lead alloy die casting parts of fishing sinker, Luya bait by vertical die casting machine

Statement of different material die casting machines usage:

Cold chamber die casting machines normally used to produce big size & heavy parts. Die casting parts material involve: Aluminum, Magnesium, Copper/Brass, Zinc/Zamak, Lead/PB etc.

Hot chamber die casting machines used to produce low melting point alloy, and with high precision. Such as Zinc/Zamak, Tin, Lead/PB die casting parts.

Advantages of Die Casting Machines Classification by Different Materials

Die casting machines have several advantages over other manufacturing processes. Some of the advantages are:

Cost-Effective

Die casting machines are highly cost-effective compared to other manufacturing processes. They can produce high-quality parts at a fast rate, reducing production costs.

High-Quality Parts

Die casting machines can produce high-quality parts with precision and accuracy. This makes them an ideal choice for manufacturers who require high-quality parts.

Large Production Quantities

Die casting machines can produce large quantities of parts in a short period. This is ideal for manufacturers who require a high volume of parts.

Reduced Waste

Die casting machines produce minimal waste, reducing the overall cost of production. This makes them an ideal choice for manufacturers who are looking to reduce their carbon footprint.

Conclusion

Die casting machines play a crucial role in the manufacturing process. They are responsible for producing high-quality metal parts and products in large quantities. The classification of die casting machines by different materials helps manufacturers choose the right machine for their specific needs. Understanding the advantages of using die casting machines can help manufacturers improve their production processes and reduce costs.

In conclusion, choosing the right die casting machine is critical for any manufacturer looking to produce high-quality metal parts and products. By understanding the die casting machines classification by different materials, manufacturers can make an informed decision and choose the right machine for their needs.

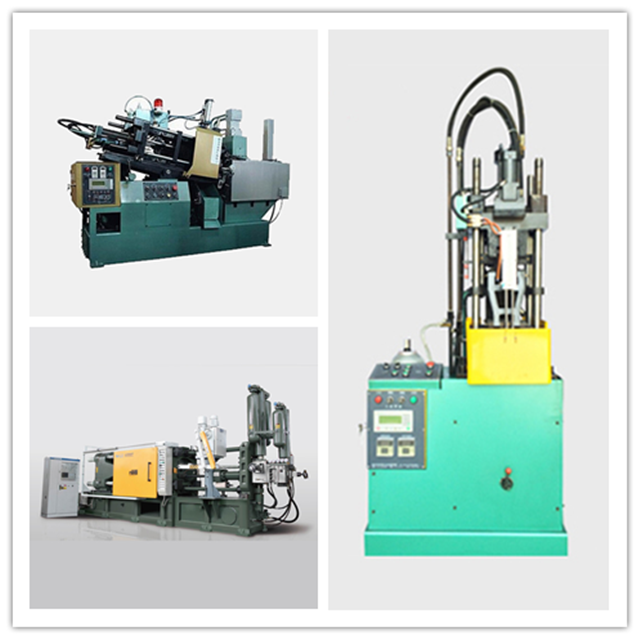

KYLT Industrial as one of Die casting machine manufacturer supplier & factory, we provide wide ranges of Vertical, Horizontal, Hot chamber, Cold Chamber die casting machines price and mold making service: cnkylt@aliyun.com

FAQs

Q1. What is die casting?

A1. Die casting is a manufacturing process that involves the production of metal parts and products. It is a cost-effective and efficient method of producing high-quality metal products in large quantities.

Q2. What are the different types of die casting machines?

A2. Die casting machines can be classified into several types based on the materials used in the manufacturing process. The most commonly used types are aluminum, zinc, magnesium, copper, and lead die casting machines.

Q3. What industries use die casting machines?

A3. Die casting machines are widely used in several industries, including automotive, aerospace, electronics, and manufacturing.

Q4. What are the advantages of using die casting machines?

A4. The advantages of using die casting machines include cost-effectiveness, high-quality parts, large production quantities, and reduced waste.

Q5. What is the role of die casting machines in the manufacturing process?

A5. Die casting machines are responsible for producing high-quality metal parts and products in large quantities. They are an essential part of the manufacturing process.

Q6. How do manufacturers choose the right die casting machine?

A6. Manufacturers choose the right die casting machine based on the material used, the required production quantity, and the part complexity.

Related Metal Casting Machinery:

Die Casting Machines Types:

· Battery Spine Die Casting Machine

· Cold Chamber Die Casting Machine

· Hot Chamber Die Casting Machine

· Vertical Die Casting Machine

Die Casting Machines Classification by Materials:

· Aluminum Die Casting Machine

· Magnesium Die Casting Machine

Die Casting Machines Application:

· Auto Parts Die Casting Machines

· Kitchen &Household Parts Die Casting Machines

· Lamps Light Parts Die Casting Machines

· Electric Vehicle Spare Parts Die Casting Machines

· Hardware, Jewelry, Clothing Accessories Die Casting Machines

· Tel-Communication Equipment Parts Die Casting Machines

· Garden Machinery & Electric Tools Parts Die Casting Machines

· Lead Acid Battery Terminal Bushing, Battery Positive Spine Grid Die Casting Machines

· Fishing Sinker Die Casting Machines

· Other

评论

发表评论