Vertical Die Casting Machine: An Overview of its Features and Benefits

Introduction: The vertical die casting machine is a critical tool in the manufacturing industry that has revolutionized the production of metal parts. This machine is widely used in various industries such as automotive, lead acid battery making and electronic industrial to produce high-quality and precise metal parts. It operates by injecting molten metal into a mold using high pressure, which then solidifies and forms the desired shape. This article will provide a comprehensive overview of the vertical die casting machine, including its features, benefits, and applications.

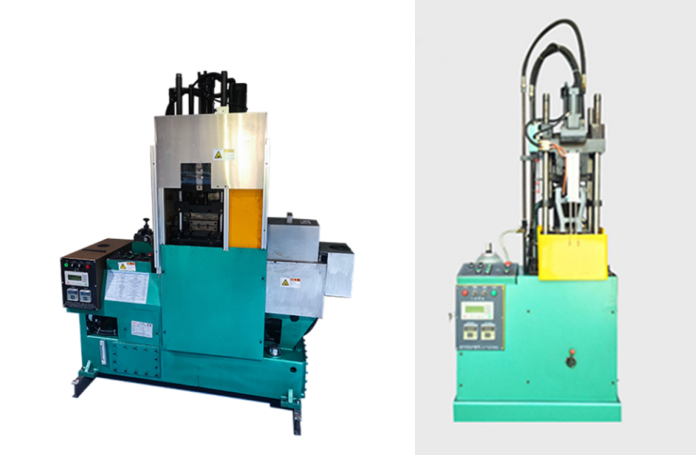

What is a Vertical Die Casting Machine?

A vertical die casting machine is a specialized type of casting machine that uses gravity to fill the mold cavity with molten metal. It is called a vertical machine because the mold is positioned vertically, and the molten metal is injected from the bottom of the mold. The vertical die casting machine is different from a horizontal die casting machine, which uses a horizontal mold and injects the metal from a horizontal position.

How does a Vertical Die Casting Machine Work?

Vertical die casting machine working method: A vertical die casting machine works by melting the metal in a furnace and then injecting it into a mold using high pressure. The mold is made of two parts, which are clamped together to create a cavity in the shape of the desired part. The molten metal is then injected into the cavity using a plunger, which exerts high pressure on the metal to ensure that it fills the cavity completely. Once the metal solidifies, the mold is opened, and the part is ejected.

Vertical Die Casting Machines Structure

Vertical die casting machines structure consists of machine body, mold clamping mechanism, injection system, cooling system, melting furance, electric system etc.

Hot Chamber Vertical die casting machines types:

12T, 20T, 30T. They are can be used cast Zinc/Zamak Alloy, Lead Alloy die casting parts, and those parts have inserts must be cast together with ZAMAK/Zinc or Lead/Pb alloy.

Applications & Usage of Vertical Die Casting Machines:

Brake wire/cable making

Lead alloy metal fishing sinker, lead metal fishing lure, lead Luya bait making

Lead acid battery terminal with bolt, copper nut manufacturing

Features of Vertical Die Casting Machine

The vertical die casting machine has several features that make it a popular choice in the manufacturing industry. Some of its notable features include:

Precision: The vertical die casting machine produces parts with high precision and accuracy, thanks to its ability to fill the mold cavity evenly and with high pressure.

High Production Rate: The machine can produce parts at a high rate, making it an ideal choice for mass production.

Reduced Scrap: The vertical die casting machine produces less scrap compared to other casting methods, which translates to lower production costs.

Consistency: The machine can produce parts with consistent quality, ensuring that the final product meets the required specifications.

Versatility: The vertical die casting machine can cast various metals, including Lead/Pb, Zamak/Zinc.

Benefits of Vertical Die Casting Machine

The vertical die casting machine has several benefits that make it a popular choice in the manufacturing industry. Some of its notable benefits include:

Cost-Effective: The machine can produce high-quality parts at a lower cost compared to other manufacturing methods, making it a cost-effective option for manufacturers.

High-Quality Parts: The machine produces parts with high precision and accuracy, ensuring that the final product meets the required specifications.

Time-Efficient: The machine can produce parts at a high rate, making it a time-efficient option for manufacturers.

Reduced Scrap: The machine produces less scrap compared to other casting methods, reducing production costs.

Easy to Use: The machine is easy to use, making it an ideal option for both experienced and novice operators.

Conclusion

The vertical die casting machine is a vital tool in the manufacturing industry that has revolutionized the production of metal parts. Its features, benefits, and applications make it an ideal choice for various industries. Whether you are in the automotive, aerospace, medical, or electronics industry, a vertical die casting machine can help you produce high-quality and precise metal parts efficiently and cost-effectively.

Investing in a vertical die casting machine can benefit your business in many ways, including increased productivity, reduced scrap, and consistent quality. As with any machine, proper maintenance is essential to keep it running smoothly and to extend its lifespan.

If you are looking for a reliable and cost-effective solution for producing high-quality metal parts, the vertical die casting machine is an excellent choice.

KYLT Industrial is your trustable Vertical Die casting machine manufacturer & supplier & factory. Get Vertical die casting machine price & die casting molds price, please email us: cnkylt@aliyun.com

FAQs

1. What is the difference between a vertical and horizontal die casting machine?

A vertical die casting machine uses a vertical mold, and the molten metal is injected from the bottom of the mold, while a horizontal die casting machine uses a horizontal mold, and the molten metal is injected from a horizontal position.

2. What are the advantages of using a vertical die casting machine?

The advantages of using a vertical die casting machine include high precision, high production rate, reduced scrap, consistency, versatility, cost-effectiveness, high-quality parts, time-efficiency, and ease of use.

3. What are the materials that can be cast using a vertical die casting machine?

A vertical die casting machine can cast various metals, including aluminum, zinc, and magnesium.

4. What industries can benefit from a vertical die casting machine?

The industries that can benefit from a vertical die casting machine include automotive, aerospace, medical, and electronics.

5. What is the typical size of a vertical die casting machine?

The size of a vertical die casting machine can vary depending on the specific application, but they can range from small machines that can produce small parts to large machines that can produce large parts.

6. How do you maintain a vertical die casting machine?

Proper maintenance is essential to keep the machine running smoothly and to prevent breakdowns. The maintenance of a vertical die casting machine includes regular cleaning, lubrication, inspection, and replacement of worn or damaged parts.

Related Metal Casting Machinery:

Die Casting Machines Types:

· Battery Spine Die Casting Machine

· Cold Chamber Die Casting Machine

· Hot Chamber Die Casting Machine

· Vertical Die Casting Machine

Die Casting Machines Classification by Materials:

· Aluminum Die Casting Machine

· Magnesium Die Casting Machine

Die Casting Machines Application:

· Auto Parts Die Casting Machines

· Kitchen &Household Parts Die Casting Machines

· Lamps Light Parts Die Casting Machines

· Electric Vehicle Spare Parts Die Casting Machines

· Hardware, Jewelry, Clothing Accessories Die Casting Machines

· Tel-Communication Equipment Parts Die Casting Machines

· Garden Machinery & Electric Tools Parts Die Casting Machines

· Lead Acid Battery Terminal Bushing, Battery Positive Spine Grid Die Casting Machines

· Fishing Sinker Die Casting Machines

· Other

评论

发表评论